COPV Series:

Scalable Pressure-Vessel Platforms

COPV-S

Satellite Class

- 0.5–5 L | ≤ 350 bar | –100 to +70 °C

- SmallSat / CubeSat propulsion & pressurization systems

COPV-L

Launcher Class

- 10–50+ L | ≤ 700 bar | 150–400 mm diameter

- Launcher pressurization & feed systems | inert / cryogenic gases

COPV-X

Experimental Series

- Configurable tanks for testing / qualification campaigns

- Optional FBG strain, thermal, and pressure sensors

Benefits

- Proven material & lay-up systems with flight heritage

- Mass-optimized for high-ΔV architectures

- Scalable manufacturing via CLS production line

Technical Capabilities & Performance Envelope

- Design: Type III to V depending on fluid

- Pressure: 1-400 bar

- Volume: 0.5 to 50 l (or larger on request)

- Fluids: cryogenic, storable, propellants, inert gases, etc.

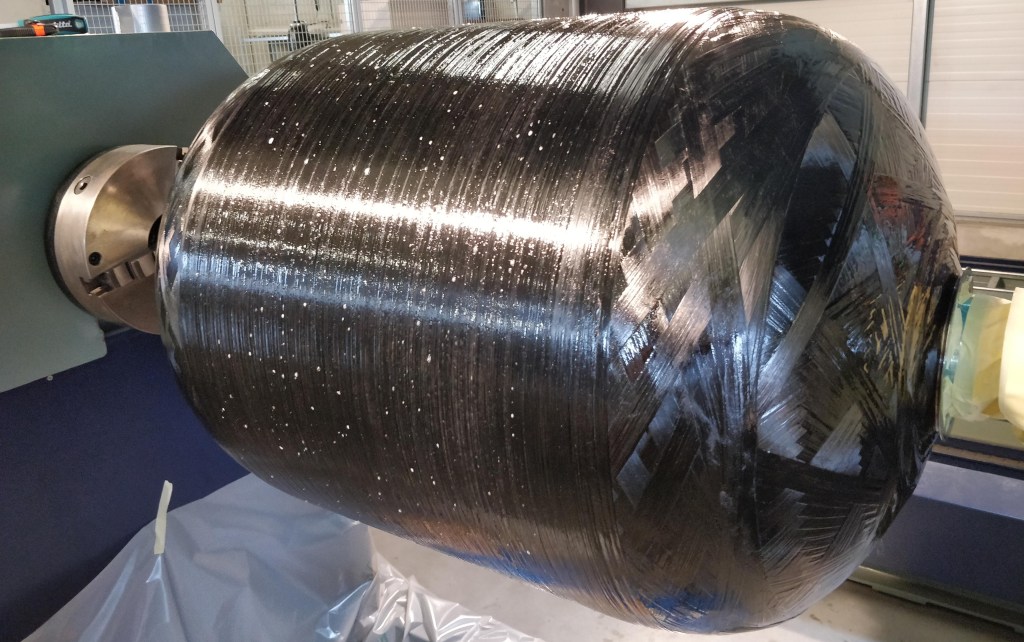

- Filament winding & AFP technologies

- Cryogenic Testing– Qualification to ECSS / EC79 / ISO 19881

CFRP Series:

Cryogenic & Structural Tanks

CFRP-Cryo | Type V Linerless

- 10–150 L | Fully cryogenic compatible (LOX / CH₄ / green propellants)

- Structural load-bearing design option

- Enables European Type V flight capability

- Up to 40% mass reduction vs. metal-lined tanks

CFRP-Prop | Type III, IV, and V

- Al / Ti liners | 10–150 L

- Hybrid CFRP + metal architecture for robustness & durability

- Broad chemical compatibility | short lead times

Type I → Type V maturity roadmap:

Enabling next-generation reusable propulsion and structural systems.